“We Add New Countries to Our Export Portfolio in 2025”

Interview: Tuğba KARADEMİR

With more than 40 years of experience in the field of textile finishing machinery, Mersan Paslanmaz Makine continues to increase its competitiveness in the global market with its patented solutions, energy-efficient technologies, and strong export network. The company is preparing to bring the point Turkish engineering has reached and its sustainable production vision together with industry professionals at ITM 2026.

While the transformation in the textile sector focused on quality, efficiency, and sustainability is accelerating, the role of machinery manufacturers that steer this transformation is becoming more critical than ever. Operating in the field of textile finishing machinery since 1983, Mersan Paslanmaz Makine steadily strengthens its position in the sector with its patented systems, environmentally friendly solutions, and strong export performance. In this interview, Mersan Makine General Manager Çağatay Sümer presents a comprehensive perspective ranging from Mersan’s foundation journey to the evaluation of 2025, from product technologies to ITM 2026 preparations.

Your company has been operating since 1983. With such a long history, what are Mersan’s foundation story and the milestones that have carried the company to its current position?

As Mersan Paslanmaz Makine, we were established in 1983 to manufacture textile finishing machinery. Since the day we were founded, we have used our accumulated knowledge and experience to determine and offer the most suitable solutions for our customers’ needs.

As Mersan Paslanmaz Makine, we were established in 1983 to manufacture textile finishing machinery. Since the day we were founded, we have used our accumulated knowledge and experience to determine and offer the most suitable solutions for our customers’ needs.

We have placed continuous development and a quality-focused approach at the center of our corporate culture. We have signed many firsts in Türkiye. Our journey, which started with tube sanforizing and thermofix machines, continued in the early 2000s when we became the first manufacturer of Gaze Machines and singeing lines in Türkiye. With the Open-Width Sanfor machine that we started producing in 2018 and our patented 3-felt Open-Width Sanfor technology, we once again made a difference in the sector and succeeded in becoming the first manufacturer.

“As Mersan, We Turned This Process into an Opportunity to Increase Our Market Diversity”

How did 2025 pass for Mersan? How do you evaluate the year in terms of production, sales, exports, and R&D / product development?

2025 was a very challenging year in which the textile sector experienced contraction on a global scale. The postponement of investments by many textile dyehouses due to financial reasons created a disadvantage for machinery manufacturers. However, as Mersan, we turned this process into an opportunity to increase our market diversity and added new countries to our export portfolio.

During this period, we made the importance we give to our existing customers more visible in the field and intensified our on-site maintenance and service services. By transferring the feedback we received from the field to our R&D center, we succeeded in advancing the technological level and efficiency of our machines to a further point.

In the textile sector, quality, efficiency, energy and resource use, and environmental sustainability stand out. How does Mersan approach these demands?

Quality and efficiency form the basis of Mersan’s production philosophy. Our preference for globally reliable brands in the equipment we use naturally carries the energy efficiency of our machines to upper standards.

We concretize our sustainability vision through the technologies we develop. For example, the SG 2400 Gaze Machine and SGD 3200 Singeing Line completely eliminate chemical use, unlike traditional methods, while providing approximately 90% water savings. From design to production, we act with environmental awareness in all our processes.

“Since 1983, We Have Been Developing Technologies That Increase the Competitiveness of Textile Manufacturers”

Which customer needs does your product range respond to?

As Mersan, we do not only produce machines; since 1983, we have been developing technologies that increase the competitiveness of textile manufacturers. Our product range directly responds to expectations of quality, high efficiency, and low operating costs.

As Mersan, we do not only produce machines; since 1983, we have been developing technologies that increase the competitiveness of textile manufacturers. Our product range directly responds to expectations of quality, high efficiency, and low operating costs.

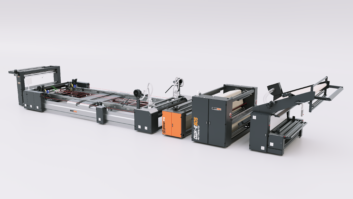

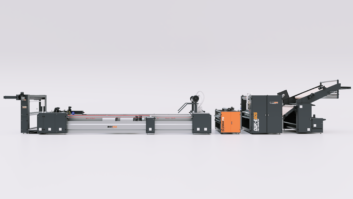

In particular, our patented 3-felt Open-Width Sanfor machine, the OWK-E605 series, provides a fabric handle quality and shrinkage performance that classical systems cannot achieve, offering our customers a significant advantage in the market.

In gaze systems, our SG 2400 and SGD 3200 models provide homogeneous singeing quality thanks to the Twinjet Singeing Burner technology developed by our own engineering, while significantly reducing operating costs with low maintenance requirements and high durability.

In addition, with our THT4 Tube Thermofix machine, which is a first in Türkiye, we reduce costs, and with our ACT AUTO, ROSS 2400, and BS X 4 machines, we provide long-term trouble-free performance in the most challenging processes of dyehouses.

“We Take Pride in Being Among the Top 5 Global Manufacturers in Our Segment”

How do you position Mersan on the export side?

We have a strong position in many strategic markets, especially South America, Central Asia, and the Far East. However, our vision is not limited to specific geographies. With our strong after-sales service network, fast spare parts supply, and ability to quickly adapt to technology, we can offer solutions to every part of the world.

Today, we have more than 1,500 operating machines and hundreds of references worldwide. We take pride in being among the top 5 global manufacturers in our segment.

“We Will Take Part in ITM 2026 with the Most Up-to-Date Outputs of Our R&D Studies”

What does ITM 2026 Exhibition represent for Mersan?

The ITM Exhibition is not only a promotion area for us; it is a strategic platform where we meet the global textile sector in our own home. At ITM 2026, we will take part with the most up-to-date outputs of our R&D studies.

Our patented 3-felt Open-Width Sanfor machine and our singeing systems with Twinjet technology will be the focal points of the exhibition. We aim to convey not only our machines to our visitors, but also our sustainable production solutions that provide energy efficiency, water savings, and ease of maintenance. We invite all sector stakeholders to our stand to closely see Mersan’s innovative vision.