New Era in Textile Industry with Superba Smart Automation Move KR1

Interview: Tuğba KARADEMİR

With the advanced automation solutions it has developed, Superba aims to increase productivity, reduce labor dependency and standardize quality not only in the textile industry but also in all industries that produce with bobbins. Raphaël Boulmeau, Vice-President of Sales at Superba; “With the commissioning of the KR1 automatic knotting robot, we now see every manufacturer using bobbins as our potential customer.”

While the importance of automation and digitalization in the textile industry is increasing day by day, Superba continues to pioneer this transformation with its innovative solutions. Offering sustainable and efficient systems to manufacturers in the face of rising costs and difficulties in finding qualified labor, the company draws attention especially with its KR1 automatic knotting robot. With its investments both in the Turkish market and on a global scale, Superba aims to become a strong player not only in textile machinery but also in smart production technologies.

KR1 Not Just a Machine, but a Production Partner

How was the year 2024 for your company? Can you evaluate it in terms of your production volume, orders and export markets?

Today, the industry in general, and the Turkish industry in particular, are facing numerous increases related to the international situation and rising labor costs. One of the solutions is automation. In this context, Superba has developed assistance systems for knotting, handling, and quality control.

Today, the industry in general, and the Turkish industry in particular, are facing numerous increases related to the international situation and rising labor costs. One of the solutions is automation. In this context, Superba has developed assistance systems for knotting, handling, and quality control.

For several years now, and increasingly so, we have seen the need to keep the industry local. Outsourcing may seem like a solution, but another option is to invest in automation to reduce costs and retain local skills in Turkiye. This is similar to what already exists in many industrial sectors such as chemistry, automotive, and food processing.

We decided to diversify our offer and Superba is developing automation solutions for our customer. This business unit is a complement to our traditional portfolio of textile machineries.

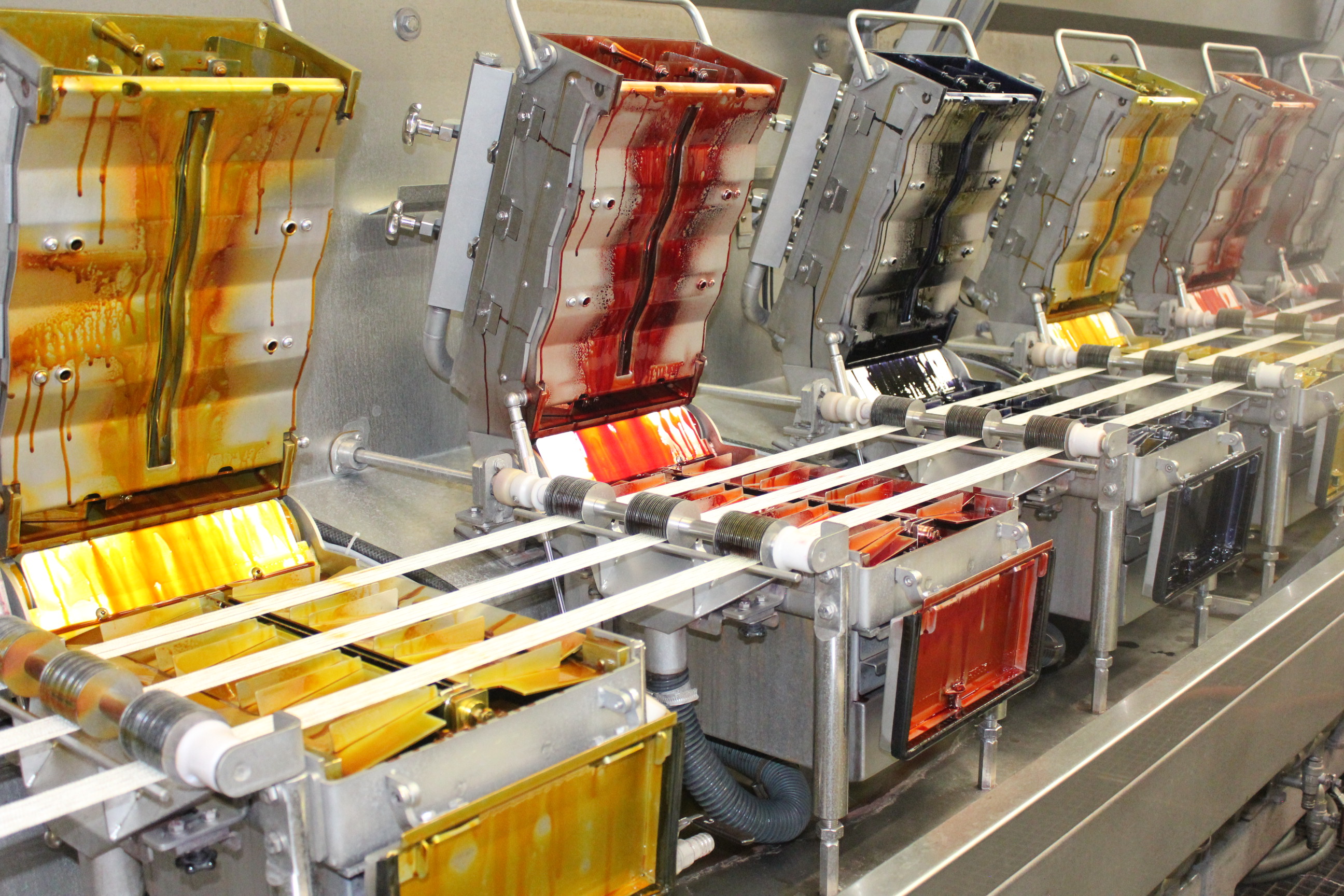

Superba’s KR1 solution is an automatic system to handle and knot bobbins combine with visual control that can be used in many industrial applications, from the finest to the most sophisticated yarns: POY, DTY, BCF, Spandex, Artificial Turf, Tire Cord, Tape & more.

With the KR1, Superba’s commitment to help customers improve productivity endures, specifically with the use of an industrial robot running 24/7. The solutions are suitable for

Which are the key global markets in which Superba has a strong presence and the emerging markets which are promising for the future? What is the importance of the Turkish market for Superba?

Automation is globally a hot topic. Any industrial company who is using bobbins of yarn is interested is reducing their handling stages and link equipments between them. Turkish market is already using automation in many applications. Our solutions are suitable for new manufacturing investment. We also propose personal designing approaches to existing installations.

Automation is globally a hot topic. Any industrial company who is using bobbins of yarn is interested is reducing their handling stages and link equipments between them. Turkish market is already using automation in many applications. Our solutions are suitable for new manufacturing investment. We also propose personal designing approaches to existing installations.

“Energy efficiency is an integral part of our development processes”

Sustainability is an important subject for textile manufacturers all around the world, what is Superba’s sustainability policy?

Energy efficiency is an integral part of our development. At Superba, we always try to limit energy consumption when improving our existing machines or developing new ones. Our R&D department works tirelessly to improve these aspects, and we are proud of the way this aspect is developing internally, but also with our customers. Thanks to more advanced automation and more precise control of the inventory in production, this allows to reduce overall costs, as well as energy and labor. Developing technologies and strengthening offerings in automation confirm Superba’s desire to assist customers in manufacturing optimized products, with a better controlled production cost.

Finally, these constant efforts to design machines with optimization in terms of energy consumption represents an important issue for Superba. It is significant because these efforts allow our customers to reduce their carbon footprint. This is the vision that we want to convey to our customers upto the consumers of the finished product.

Reducing production costs is a priority for all textile factories, how your machinery can help manufacturers in this field?

To compensate for a range of factors such as inflation and various tariff increases, the industry needs to reduce operational costs. The solution lies in automation. Reducing manufacturing costs by replacing operators and implementing quality control devices. Automation helps to overcome difficulties in finding labor. It allows for the performance of repetitive operations with high physical constraints. Efficiencies are improved and do not depend on physiological parameters.

Digitalization is a great step to create a common language to achieve more productivity and simplicity. How does Superba implement digitalization in textile and nonwoven machinery production? And why it is important?

Data are collected from the KR1 automation cell. The digitalisation allows our customers to improve their production planning, traceability and proactively organize the maintenance agenda. The KR1 can collect the necessary data for the Manufacturing Execution System (MES) to best optimize the production. Fast developments in this field already allow the use of digital clones of machines. Additionally, the use of artificial intelligence (AI) enables our vision control systems to calibrate by expanding the database and to validate or reject bobbins. Its deep-learning vision system detects defects instantly (mix-ups, twists, impurities), ensuring superior quality control beyond human capability.

Which kind of innovations, trends and progress is expected in the upcoming years in the heat-setting and carpet yarn sector?

We are present in different fields where yarn bobbins need to be transported. It’s suitable for a lot of different type of yarn like POY, DTY, BCF, Spandex, Artificial Turf, Technical Yarns, Tire Cord or Tape. This knotting machine able a production line working 24/7, allowing customers to improve their productivity. Heat-setting has long been a core area of expertise for us. With the introduction of the automatic knotting robot KR1, we now cater to all bobbin users as potential customers.

As a company, do you have new investments and new machine developments on your agenda in the near future? Can you tell us about your 2025 targets?

In the dawn of a new era where artificial intelligence (AI) is becoming increasingly prevalent in enhanced digitalization and automation of our companies, harmonization of technology and sustainability are goals. At Superba, we are convinced these goals go hand in hand. This is why we developed automatic knotting system assisted by a robot. The KR1 system can be used in many industrial branches, enables to handle, pack, label and quality control of bobbins.